What are the differences between full lamination technology and non full laminat

Full lamination technology achieves comprehensive surpassing in display effect, touch experience, lightweight and structural strength by eliminating air layers, which is a revolutionary upgrade of non lamination technology

What are the differences between full lamination technology and non full lamination technology?

Full lamination and non full lamination technologies are the core differences that affect screen display and touch experience. A simple analogy is:

Full lamination: Like a sandwich, all layers (protective glass, touch layer, display layer) are precisely and seamlessly bonded together.

Non full fit: like a "sandwich biscuit", there are obvious air gaps between each layer.

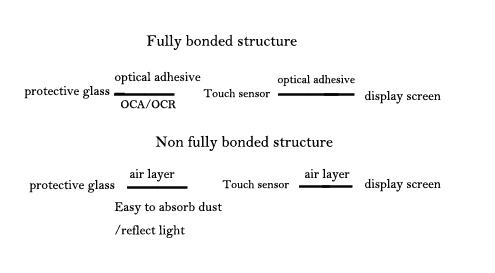

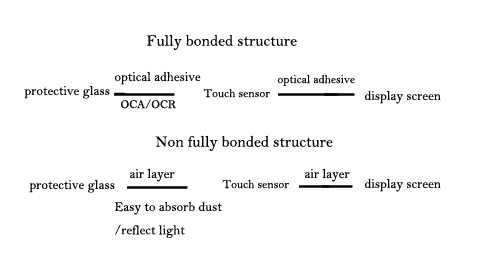

The following diagram visually illustrates the core structural differences between the two technologies:

Based on this core difference, we will compare from several aspects:

Detailed explanation of core differences

1. Optical performance (the most intuitive difference)

Non full lamination:

Severe reflection: The air gap between layers causes light to reflect multiple times between the glass and screen, making it almost impossible to see the content clearly under strong light (such as outdoors).

Poor transparency: After light is refracted through the air layer, the color and contrast will be reduced, making it look like "looking at a screen through frosted glass", with a non transparent and gray image.

Full Fit:

Significantly reduce reflection: The refractive index of optical adhesive is close to that of glass, eliminating internal reflection and significantly improving visibility under strong light.

Transparent and vivid display: The light passes directly through with almost no loss, the colors are more saturated, the contrast is higher, and the image seems to be "floating on the glass surface".

2. Structural strength and sealing performance

Non full lamination:

Easy to attract dust: The air layer is connected to the outside through the gaps in the frame, and may accumulate dust in the interlayer after long-term use, which cannot be cleaned.

Loose structure: When pressing the screen, there is a "hollow feeling", and each layer is relatively independent, with weak impact resistance.

Full Fit:

Good sealing: Each layer is tightly bonded, eliminating the problem of dust ingress.

Sturdy structure: The overall structure is more robust, with stronger resistance to impact and pressure.

3. Touch experience

Non full lamination:

Touch not following hands: Due to the distance between the touch layer and the display layer, there is a "parallax" between the landing point of the finger/stylus and the screen cursor, especially when viewing the screen from the side.

Touch noise: Pressing may produce a "click" sound due to squeezing the air layer.

Full Fit:

Precise touch following: The touch layer is closely attached to the display layer, with almost no parallax, more precise strokes, and direct tactile sensation.

Solid touch: The pressing sensation is solid, and the operation feedback is better.

4. Thickness and weight

Non full fit: Space needs to be reserved for the air layer, resulting in thicker and heavier equipment as a whole.

Full lamination: Each layer is tightly adhered, making it thinner and in line with the trend of modern electronic devices becoming thinner and lighter.

5. Maintenance costs and processes

Non full lamination:

Easy maintenance and low cost: each layer can be replaced separately. For example, if the outer screen glass is broken, only the glass needs to be replaced, and the cost is low.

Full Fit:

Difficulty in maintenance and high cost: The layers are tightly bonded, and during maintenance, it is usually necessary to replace the entire module of "glass+touch+display" together (commonly known as the "assembly"), which is costly. In the later stage, more complex "screen separation" technology was also developed, but the process requirements were high.

Summary and Common Applications

Feature | Full Fit Screen | Non full lamination screen |

Display effect | Transparent, bright, and minimally reflective | Gray, white, and heavily reflective |

Outdoor visibility | Excellent | Very poor |

Touch experience | Accurate, responsive, and no empty noise | There is parallax and a sense of emptiness |

Thickness/Weight | slimmer and lighter | More substantial |

Home sealing | Good, no dust in | Poor, there may be dust entering |

Maintenance cost | Very high (requires replacement of assembly) | Lower (replaceable layer by layer) |

Manufacturing cost | Expensive | Cheap |

Application scenarios

Full lamination technology has become a standard configuration for mainstream consumer electronics products such as smartphones, high-end tablets, laptops, and digital cameras.

Non full lamination technology: Currently, it is mainly used for low-end devices, industrial control devices, calculators, early or low-priced tablets that do not require high display effects and touch control. Due to its extremely low maintenance costs, it still has a market in some specific fields (such as teaching tablets and children's devices).

Conclusion: Full lamination technology has achieved comprehensive surpassing in display effect, touch experience, lightweight and structural strength by eliminating the air layer, and is a revolutionary upgrade of non lamination technology. The only disadvantage is the high maintenance cost. Users should prioritize products with fully integrated screens when purchasing equipment, unless their budget is extremely limited or they are particularly concerned about subsequent maintenance costs.