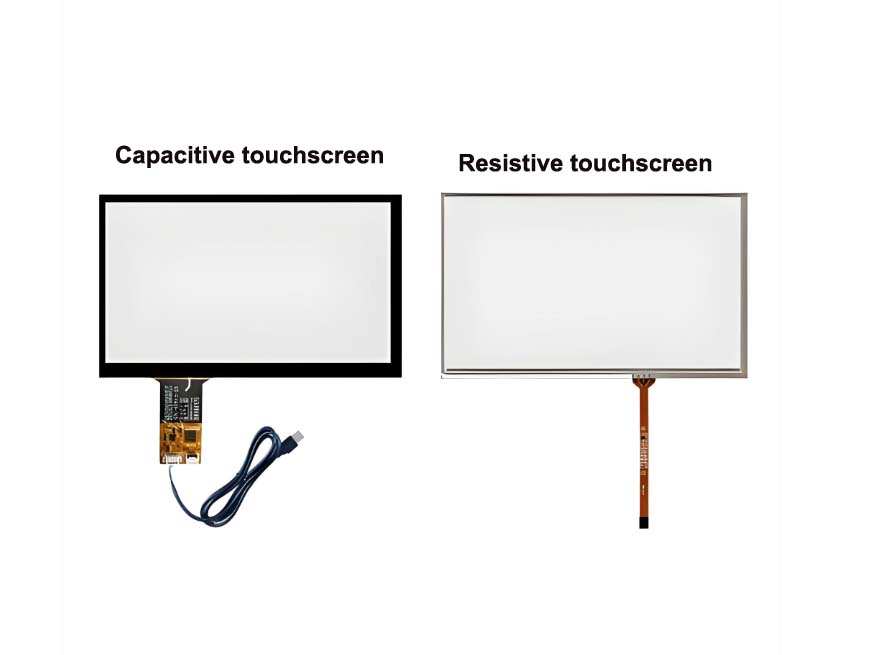

What is the difference betweenresistive touch screen and capacitive touch screen

The working principles of resistive touch screens and capacitive touch screens are fundamentally different, resulting in their completely different characteristics, experiences, and application scenarios.

What is the difference between the working principle of resistive touch screen and capacitive touch screen?

The working principles of resistive touch screens and capacitive touch screens are fundamentally different, resulting in their completely different characteristics, experiences, and application scenarios.

Here is a detailed comparison of their working principles, which you can understand from a core concept:

Resistive screen: The working principle is based on "force" and is physical contact.

Capacitive screen: The working principle is based on "electricity", which is charge induction.

Below, we will make a detailed comparison from five dimensions:

1. Comparison of core principles

Feature | Resistive touch screen | Capacitive touch screen |

Principles of Physics | Pressure sensing. A circuit is formed through the physical contact of two layers of conductive thin films. | Capacitive induction. Coupling away the charges in the electrostatic field of the screen through conductive objects such as fingers. |

The essence of work | Mechanical switch. It is necessary to deform the film to connect the circuit. | Electric field sensor. Detect changes in local capacitance (the ability to store charges). |

Trigger condition | Pressure must be applied to bend the upper film. | Just touch or approach lightly, no need to press hard. |

2.Comparison of Structure and Operation Methods

feature | Resistive touch screen | Capacitive touch screen |

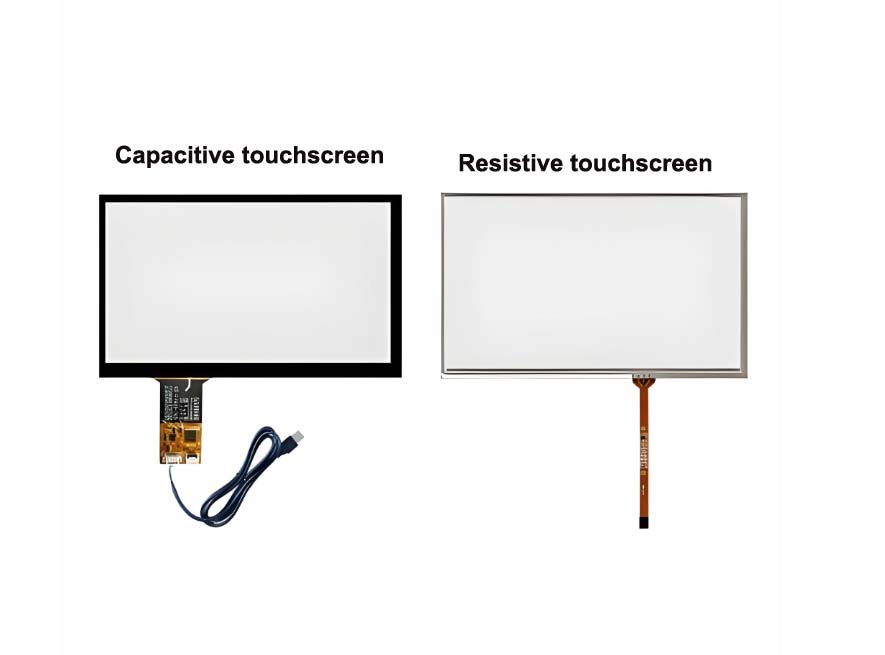

Structure | Like a sandwich: two separate layers of ITO conductive film (flexible layer+rigid layer) with isolation points in between. | Like "fine grid": Etching a transparent electrode array criss crossing on a single-layer glass substrate to form capacitor nodes. |

Operating objects | Any object is acceptable. Fingers (with or without gloves), stylus, nails, keys, etc., as long as pressure can be applied to deform the film. | It must be a conductive object. Usually it is a finger skin, specialized capacitive pen (pen tip conductive). Ordinary gloves and insulated pens are ineffective. |

Touch experience | There is a feeling of 'pressing', which may require calibration. | Very sensitive and smooth, supporting light touch and sliding. |

3.Comparison of Performance and Functional Features

feature | Resistive touch screen | Capacitive touch screen |

Multi touch | Basically not supported (can only recognize one contact at a time). | Native support. It can recognize multiple touch points simultaneously, enabling pinching, zooming, multi finger gestures, and more. |

Precision | High, suitable for fine clicking and writing. | Very high, modern technology can achieve pixel level accuracy. |

Transmittance | Low (about 75% -85%), the multi-layer structure causes the screen to appear dark and gray. | Very high (>90%), closer to pure glass, with bright and beautiful display effects. |

Durability | The surface is made of flexible plastic film, which is easily scratched. Repeated pressing may cause fatigue damage to the film. | The surface is made of tempered glass, which is very scratch resistant, but it will shatter upon strong impact. |

Environmental adaptability | Not afraid of water, oil, and dust (as long as there is no pressure or accidental contact), suitable for complex environments. | Afraid of water stains, sweat stains (which can cause accidental contact due to conductivity), and afraid of strong static electricity interference. |

Cost | The manufacturing process is simple and the cost is low. | The manufacturing process is complex and the cost is high. |

4.Working principle and process image metaphor

Resistive screen: like a "coordinate paper button".

1. You press a point on the screen with your finger.

2. The upper "plastic coordinate paper" is bent and touches the lower "coordinate paper".

3. The controller immediately measures the voltage values of this contact point on the X and Y axes.

4. Calculate the precise (X, Y) coordinates based on the voltage values.

Capacitive screen: like an 'electrostatic spider web'.

1. The screen surface is covered with invisible and stable static electric fields (spider webs).

When your fingers (conductors) approach, they will "suck up" some of the charges on the power grid around the touch point.

3. The controller scans the entire power grid hundreds of times per second and finds that the charge at certain nodes has decreased.

4. Accurately locate the touch point by calculating the location of the node with the most charge reduction. When touching multiple points, it is to simultaneously locate the positions of multiple 'charge depressions'.

5. Summary of Typical Application Scenarios

Resistive screen: Due to its low cost, strong anti-interference, and non selective operation characteristics, it is commonly used for:

Industrial control equipment, medical instruments, workshop machine tools.

Supermarket POS machines, bank ATM machines (some old models).

Outdoor equipment and low-temperature environment equipment that require wearing gloves for operation.

Low end navigation devices, early PDAs, and smartphones.

Capacitive screen: Due to its sensitivity, support for multi touch, good display effect, and durability, it has become the absolute mainstream of modern interaction, used for:

All modern smartphones, tablets, and smartwatches.

Touchpad and touchscreen for laptops.

Smart home control panel, car central control screen.

High end information inquiry machines and vending machines.

summary

Simply put, a resistive screen works when pressed down, while a capacitive screen works when touched. The fundamental principle difference directly determines that capacitive screens can provide a more natural, rich, and beautiful touch experience, thus dominating the consumer electronics market. And resistive screens continue to play an irreplaceable role in their specific professional fields that require reliability and environmental adaptability.