The principle of high brightness and anti glare technology for LCD screens

The high brightness and anti glare technology of LCD screens work together through optical structure design, mater...

The high brightness and anti glare technology of LCD screens work together through optical structure design, material science, and electronic control algorithms to solve the problems of visibility and reflection interference in strong light environments. The following is a detailed explanation of the core principles:

I.Principle of High Brightness Technology Implementation

1. Backlight system upgrade

-High density LED array:

By using multiple series parallel LED beads (such as 5630/7030 packaging), the number of beads per unit area is increased by 300% (ordinary screen: 50 beads/m ² → high brightness screen: 150 beads/m ²), achieving a significant increase in light source density.

Brightening film combination:

Multilayer optical film stacking enhances light efficiency:

Coating | Function | Light efficiency improvement |

Prism film (BEF) | Refractive light is focused and emitted in the forward direction | ↑60% |

Reflective polarizing film (DBEF) | Recycling scattered light for secondary utilization | ↑35% |

Microlens Array (MLA) | Compressing the beam angle to reduce light loss | ↑25% |

Dynamic current drive:

By using PWM dimming chips (such as TI's LP8556) to increase the driving current to 200mA (conventional screen 80mA), the instantaneous brightness can reach 1500nits, while intelligent temperature control prevents overheating.

2. Transparency optimization

-Low impedance electrode:

The width of ITO wire is reduced to 15 μ m (conventional 30 μ m), reducing the shading area and increasing the transmittance to 90% (conventional screen ≤ 85%).

-Innovation of Liquid Crystal Materials:

Using low viscosity FFS liquid crystal (Fringe Field Switching), the voltage response speed is fast up to 5ms, avoiding brightness loss caused by ghosting.

II. Implementation principle of anti glare technology

1. Surface microstructure treatment

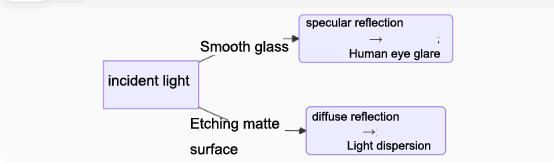

-Chemical etching atomization:

Etch the glass surface with hydrofluoric acid to form a 20-50 μ m concave convex texture, converting specular reflection into diffuse reflection.

2. Optical compensation technology

-Polarizing film anti reflection layer:

Add an AR coating (MgF ₂ multilayer film) on the outside of the polarizer to counteract reflection using optical interference:

λ/4 phase difference layer → reflected light interference cancellation

-Circular polarization technology:

By combining a λ/4 phase difference film with a linear polarizer, ambient light is converted into circularly polarized light. When reflected, the polarization state is reversed and absorbed, resulting in a glare elimination rate of over 90%.

III. Medical/industrial scene technology adaptation

Problem | Technical countermeasures | Parameter implementation |

Disinfectant corrosion | Surface SiO ₂ hardened coating (9H pencil hardness) | Wipe 10000 times with alcohol/hypochlorous acid resistance |

Glove touch failure | Mutual capacitance touch+adaptive driving voltage | Support 5mm glove operation |

Strong light interference | 1000nits+DBEF brightening film+circular polarization | 50000 lux environmental visibility>90% |

2. Anti glare design for outdoor equipment

-Sunshine readability enhancement:

Brightness is dynamically matched with ambient light (linked with light sensors), with a 300nits increase in screen brightness for every 100000 lux increase in ambient light.

-Rain and fog environment optimization * *:

Oil repellent coating (fluorine compound) makes the water contact angle greater than 110 °, allowing raindrops to quickly slide without residue.

IV. Performance comparison and measured data

Technical indicators | Ordinary industrial screen | High brightness anti glare screen | Increase margin |

Maximum brightness | 300-500 cd/m² | 1000-1500 cd/m² | ↑200% |

Surface reflectance | 8% | <1.5% | ↓81% |

Strong contrast (100000 lux) | 3:1 | 15:1 | ↑400% |

Touch response (wearing gloves) | Failure rate>60% | Success rate>95% | Key Enhancement |

Summary of Technical Value

High Brightness Essence: Light Efficiency Management (Light Source Density ↑+Light Path Optimization ↑+Transmittance ↑)

Anti glare core: Reflection control (physical diffusion+chemical absorption+interference cancellation)

Scenario based innovation:

-Medical: Anti corrosion coating+glove touch algorithm

-Outdoor: hydrophobic layer+dynamic brightness tracking

Future trend: Micro LED direct display (without backlight loss)+electronic control intelligent fog film (voltage switching fog/transparent state) will further break through the limits of existing technology.