In Cell and On Cell technologies Analysis of Differences in Core Structure

The fundamental difference between In Cell and On Cell technologies lies in the integration location of touch sen

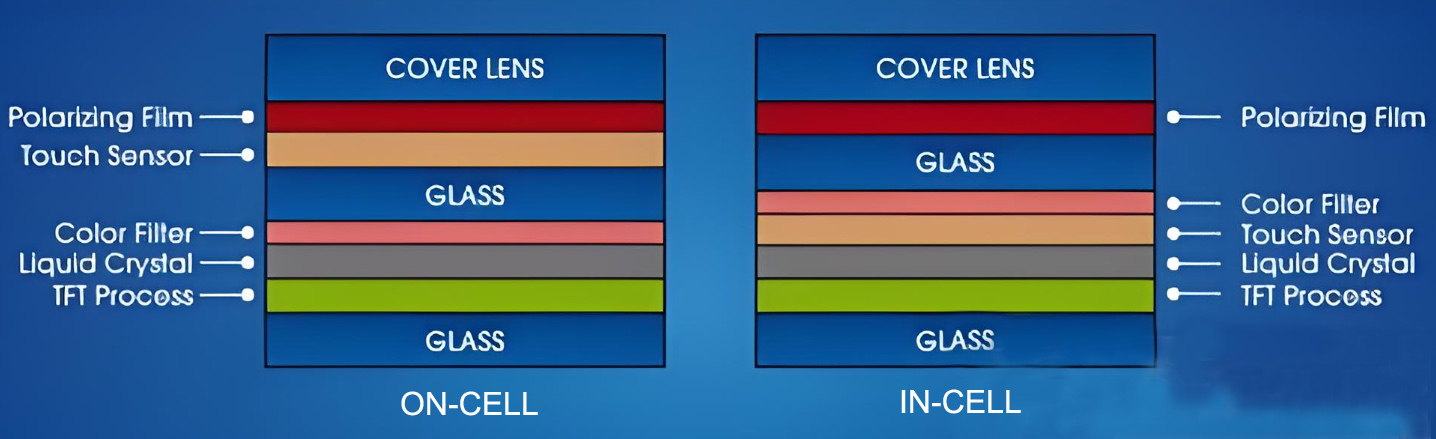

The fundamental difference between In Cell and On Cell technologies lies in the integration location of touch sensors, which directly determines the performance and manufacturing difficulty of the two technologies. Understanding these structural differences is key to grasping the essence of the two technologies.

In Cell technology adopts the design concept of "intracellular localization", directly embedding touch sensors into the liquid crystal pixel layer and fully integrating with the liquid crystal layer. This "embedded" structure eliminates the independent touch layer in traditional touch technology, resulting in a significant reduction in the overall thickness of the screen, typically below 3.5mm. In the In Cell structure, the touch function is integrated into the liquid crystal cell, and all touch screen structures are located between the upper and lower glass substrates of the LCD, achieving true integration of touch and display. This highly integrated design enables devices such as the iPhone 5 that use In Cell technology to achieve an unprecedented lightweight experience.

In contrast, On Cell technology adopts the design concept of "intercellular localization" and belongs to a "plug-in" integrated solution. It embeds the touch sensor independently between the color filter (CF) substrate and polarizer of the liquid crystal panel, rather than directly fusing with the liquid crystal layer. This structure means that the touch layer and the liquid crystal layer remain relatively independent, and only a simple transparent electrode pattern needs to be formed between the color filter substrate and the polarizing plate to achieve touch functionality. From a technical implementation perspective, as long as there is a touch screen structure located outside the glass substrate on the LCD, it belongs to the On Cell structure.

Table: Comparison of In Cell and On Cell Technology Structures

Technical features | In Cell technology | On Cell Technology |

Touch layer position | Inside the LCD pixel layer | Between color filter and polarizer |

Structural type | Fully embedded | Semi embedded/external plug-in |

Typical thickness | Below 3.5mm | About 4mm |

Technical difficulty | Extremely high, requiring precise integration of touch and LCD layers | Relatively low, the touch layer is independently encapsulated |

Representative product | iPhone5、Lumia920 | Samsung Galaxy S series AMOLED screen |

In terms of integration, In Cell represents a higher level of touch integration technology, which delves touch functionality into the display core; On Cell is a compromise solution that strikes a balance between integration and process difficulty. This fundamental difference in structure directly leads to a series of differences between the two in manufacturing processes, performance, and application scenarios, which we will explore in detail in subsequent chapters.

Manufacturing Process and Cost Analysis of In Cell and On Cell Display Technologies

There are significant differences in production process complexity and manufacturing costs between In Cell and On Cell technologies, which directly affect manufacturers' technology choices and the possibility of large-scale production. Understanding the differences in manufacturing levels can help explain why devices with different positioning adopt different touch technology solutions.

The manufacturing process of In Cell technology is extremely complex because it requires precise fusion of the touch layer and the liquid crystal layer, and requires embedding touch sensors and matching touch ICs inside the liquid crystal pixels. This process faces two main challenges: firstly, it must accurately control the interference between touch signals and display signals, otherwise it is easy to cause erroneous touch sensing signals or excessive noise; The second is the extremely high requirement for the cleanliness of the production environment, and any small impurities may cause screen defects. This high difficulty manufacturing process directly leads to a low yield rate of In Cell panels and a corresponding increase in production costs. At present, only a few high-end models such as Apple iPhone and Nokia Lumia adopt this technology, partly due to its high cost.

In contrast, the manufacturing process of On Cell technology is relatively simpler. Due to the touch layer being located between the color filter substrate and the polarizing plate, a simple transparent electrode pattern only needs to be formed, without the need for film formation on both sides of the upper glass substrate. This design greatly simplifies the production process. This technological advantage makes it easier for On Cell panels to ensure high yield and correspondingly reduce manufacturing costs. Samsung, Hitachi, LG and other manufacturers are able to make rapid progress in On Cell structured touch screens largely due to the relatively low process threshold of this technology.

From a supply chain perspective, the two technologies have also brought about different industrial transformations. In Cell technology requires display panel manufacturers to have a high degree of touch technology integration capability, which essentially blurs the boundary between traditional display panel manufacturers and touch panel manufacturers. The popularization of On Cell technology has prompted manufacturers of touch panels to shift from external touch panel business to LCD panel and color filter business, completely changing the original supply chain structure.

Table: Comparison of Manufacturing Processes between In Cell and On Cell Technologies

Process indicators | In Cell technology | On Cell Technology |

Process complexity | Extremely high, requiring precise integration of touch and display | Medium, the touch layer is relatively independent |

yield rate | Low, difficult quality control | High, relatively stable production |

Cost factors | Expensive, only for flagship devices | Moderate, suitable for mid to high end equipment |

Technical threshold | Need strong research and development capabilities | Existing panel manufacturers are relatively easy to transform |

Supply chain impact | Integrate touch and display supply chain | Transforming the role of traditional touch panel manufacturers |

It is worth noting that although On Cell technology has significant advantages in terms of process difficulty and cost, it also faces some specific challenges, such as difficulty in thinning and color unevenness that may occur during touch. These technological limitations have to some extent hindered the further development of On Cell technology, and many experts believe that it may only be a transition to more advanced In Cell technology。