The difference between dark spots and bright spots on LCD screens

Professional analysis of dark spots and bright spots on LCD screens, including differences and comparisons, causes and effects, applicable to product documentation and technical popularization

Professional analysis of dark spots and bright spots on LCD screens, including differences and comparisons, causes and effects, applicable to product documentation and technical popularization:

The core difference between dark spots and bright spots on LCD screens

Characteristic | Dead Pixel | Stuck Pixel/Bright Dot |

Display Status | Permanently non luminous, black in color | Permanently bright, presenting a fixed color of white/red/green/blue |

Cause | Physical damage to LCD unit or failure of TFT transistor | LCD unit stuck or signal circuit malfunction |

Visible Scene | Obvious on a light background (such as a white screen) | Obvious under dark background (such as black screen) |

Visual impact | Similar to the image 'missing' | Similar to visual "pollution" (especially when watching movies in dark environments) |

Repairability | Irreparable (physical damage) | A few can be temporarily restored through pixel repair software |

Deep analysis of technical principles

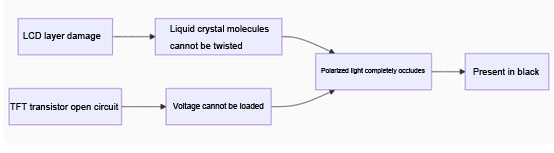

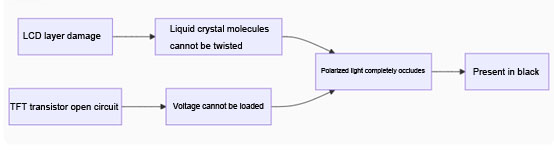

Mechanism of dark spot formation

Mechanism of Highlight Formation

Special effects in industrial scenarios

Medical display equipment

Dark spot: may be misdiagnosed as tissue shadow (such as X-ray observation)

Highlight: Easy to be misjudged as calcification or bleeding points

▶ Industry standard requirement: 0 bad pixels (Class 1 level)

Industrial control screen

Dark spot: causing missing key data in the monitoring screen

Highlight: Interference alarm status recognition (such as misjudging the red alarm light)

▶ Allow ≤ 3 bad pixels (Class 2 level)

Car display screen

Nighttime highlights: Diverting the driver's attention (similar to direct high beam)

Dark spot: Risk of loss of navigation key intersection information

User authentication method (three-step self check)

1. Complete solid color testing method

Black Screen → Observe Highlights

Full white screen → Observe dark spots

Three primary color testing → Identify color highlights

2. Magnifying mirror assistance

Highlight: Fixed position illumination (non screen dust)

Dark spot: No sub-pixel emission (different from small foreign object occlusion) 3

Professional tool validation

Automatically scan using software such as Dead Pixel Test

Industrial grade testing: Microscopic camera+image analysis system

Industry Quality Standard (ISO 13406-2 Specification)

Bad dot type | Class 1(Medical) | Class 2(Industrial grade) | Class 3(Consumer Grade) |

Dark spot | 0 | ≤2 | ≤5 |

Highlights | 0 | ≤2 | ≤5 |

Three color highlights | 0 | ≤1 | ≤3 |

Total number of bad pixels | 0 | ≤3 | ≤8 |

Purchase suggestions

1. Industrial/Medical Equipment

Request the supplier to provide a distribution map of bad pixels and a Class certificate

The contract states: "Upon arrival inspection, bright/dark spots exceeding the standard were found, and the entire batch was returned“

2. Consumer grade products

National standards allow for the presence of bad pixels (such as laptop screens with ≤ 3)

Priority should be given to brands that provide "zero bad point guarantee" (with a premium of 10-15%)

3. Basis for Rights Protection

O Keep unboxing inspection videos

According to Article 7 of the "Three Guarantees Regulations for Monitors": "If there are more than 3 bad pixels during startup, they can be returned or exchanged“

Technology trend: Micro LED technology will completely eliminate the problem of bad pixels (single pixel independent packaging), and current LCD screens still need to pay attention to the manufacturer's warranty terms