How to repair vertical stripes on LCD screens

About 60% of vertical stripe faults are caused by cable and T-Con board issues, and basic faults can be independently resolved through the steps in this article It is recommended to regularly carry out oxidation protection (apply contact oil) on the scre

Original technical guide for repairing vertical stripes on LCD screens, combined with common causes and solutions, suitable for devices such as monitors, industrial screens, televisions, etc.:

Troubleshooting and Maintenance Guide for Vertical Stripe on LCD Screen

1.Vertical stripe types and corresponding faults

Stripe features | Possible reasons | Urgency |

Single or multiple colored vertical lines | Loose/damaged wiring, screen panel damage | high |

Dense gray vertical stripes on the entire screen | T-Con board malfunction, damaged driver IC | emergency |

Vertical strip with fixed edge position | Poor screen wire contact and electromagnetic interference | medium |

Flashing and moving vertical stripes | Signal source issue, graphics card malfunction | medium |

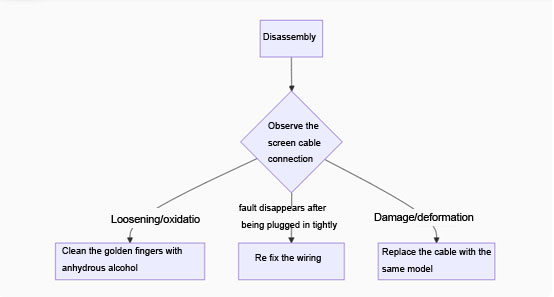

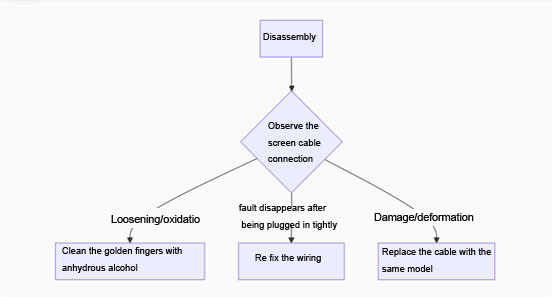

2. 6-step diagnostic and maintenance process (with operation diagram attached)

Step 1: Basic troubleshooting (30% of problems can be solved)

• Restart the device: Power off for 10 minutes to eliminate static interference

• Replace signal cable: Test if HDMI/DP/VGA cable is damaged( ⚠ Industrial screen needs to check LVDS line)

• Switch signal source: Connect other devices (such as laptops) to troubleshoot the host

Step 2: Physical testing (emphasis!)

Step 3: T-Con board diagnosis (critical maintenance point)

• Location: Under the metal shielding cover on the back of the screen

• Detection method:

1. Use a multimeter to measure the power supply voltage of the T-Con board (usually 12V/5V)

2. Gently press the main chip with your fingers to observe the changes in stripes (stripes will flash during virtual soldering)

• Solution:

Repair welding of driver IC (requires professional operation of hot air gun)

Replace T-Con board (model labeled as T320XVN01.1)

Step 4: Panel level fault diagnosis

• Press test: Gently press the screen border when turned on:

The stripes disappear → the COF binding inside the panel is loose (you can try repairing it with a screen press)

The stripes remain unchanged → the glass substrate electrode breaks( ⚠️ Cannot be repaired and requires screen replacement)

Step 5: Environmental interference elimination (common in industrial scenarios)

Strong electromagnetic source: Keep away from frequency converters/high-power motors

Grounding detection: Use a multimeter to verify that the grounding resistance of the equipment is less than 4 Ω

• Install magnetic rings: Install ferrite magnetic rings at both ends of the video cable

Step 6: Driver board/motherboard inspection

• Flashing the latest firmware (official website download)

Measure the LVDS signal voltage from the motherboard to the T-Con board (normal value 1.2V ± 0.2V)

3. Special handling for different devices

Device Type | Key focus areas | Maintenance cost reference |

Industrial touch all-in-one machine | Internal LVDS line anti-interference shielding layer | Cable laying ¥ 50-200 |

Car display screen | Voltage fluctuation of power supply stabilization module | T-Con board ¥ 80-300 |

Medical display equipment | Has the T-Con board's three proof coating peeled off | Change screen ¥ 800+ |

4.Maintenance taboos and safety regulations: Continuous electrical operation may burn out the driver IC( ⚠ Before disassembling, all power sources must be disconnected. Contact the circuit board with bare hands, use anti-static wristbands, and use non original accessories. Voltage mismatch can cause secondary damage. 5. Ultimate decision recommendation cost<300 yuan:="" prioritize="" repairing="" t-con="" board="" or="" wiring="" cost="">70% screen price: directly replace the screen with a new one (success rate of panel damage repair<20%).

Technical summary: About 60% of vertical stripe faults are caused by cable and T-Con board issues, and basic faults can be independently resolved through the steps in this article. It is recommended to regularly carry out oxidation protection (apply contact oil) on the screen line interface of industrial equipment to prevent faults from occurring. If you encounter physical damage to the panel, please contact a professional repair organization in a timely manner.

Industrial LCD screen:https://www.idtdisplay.com/

AUO LCD DISPLAY:https://www.idtdisplay.com/products/AUO_LCD_Displays/