The working principle and advantages and disadvantages of various touch screens

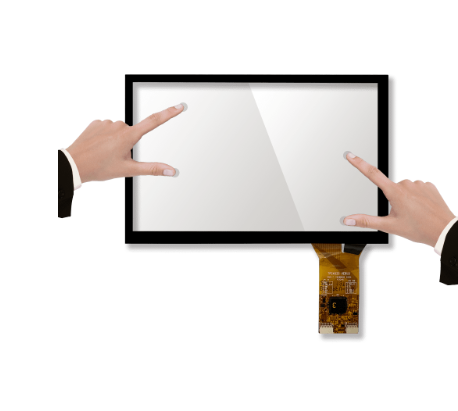

As a core component of human-computer interaction, touch screens have been widely used in many fields such as industrial control, medical equipment, self-service terminals (such as POS, Kiosk), in car systems, smart homes, educational equipment, etc

As a core component of human-computer interaction, touch screens have been widely used in many fields such as industrial control, medical equipment, self-service terminals (such as POS, Kiosk), in car systems, smart homes, educational equipment, etc. Faced with the dazzling array of touch screen technology types and specifications on the market, first we need to understand the working principles, advantages and disadvantages of different types of touch screens:

Principle: Composed of two layers of flexible thin films (usually ITO) with transparent conductive coatings, with small gaps in between. When pressed, the two layers make contact, and the controller detects the voltage change at the contact point to determine the position.

advantage:

Low cost: usually the most economical choice.

Flexible input method: can be operated with fingers (with or without gloves), stylus, nails, or any hard object.

Anti surface pollution: has a certain tolerance for water droplets, oil stains, and dust.

The structure is relatively simple.

Disadvantages:

Low transmittance (usually 75% -85%): affects display clarity and brightness.

Surface easy to scratch: The flexible surface is relatively fragile.

Not supporting multi touch (or limited support such as two-point): unable to achieve smooth multi finger gestures (such as zooming, rotating).

Requires a certain amount of pressure: not as sensitive as capacitive screens.

The outer film may be fatigued and damaged due to repeated pressing.

Typical applications: industrial control panels (operators may wear gloves), low-cost POS machines, signature boards, medical equipment (specific scenarios), and some in vehicle central control systems (old models).

Principle: Utilizing human body current induction. The glass surface is coated with a transparent conductive layer (ITO) to form an electrostatic field. When a finger touches, it causes a change in capacitance, and the controller detects the location of the change.

Type:

Surface capacitive: an early technology with low accuracy and susceptibility to environmental influences, which is now less common.

Projection capacitive: mainstream technology. Etch fine X/Y electrode grids (self capacitance or mutual capacitance) on both sides of the glass substrate. Supports multi touch and gesture recognition.

advantage:

High transmittance (usually>90%): The display effect is clearer and more vivid.

Excellent touch sensitivity: respond with just a light touch.

Supports true multi touch: enables complex gesture operations such as zooming, rotating, sliding, etc.

Hard and durable surface: The outer layer is usually made of glass (such as cover glass), which has good scratch resistance.

Long service life: no mechanical moving parts.

Disadvantages:

Relatively high cost: especially for large-sized or high specification products.

Can only be activated by conductive objects: bare fingers or specialized capacitive pens. Ordinary gloves, ordinary plastic pens, and nails cannot be operated (special conductive gloves/pens are required).

Vulnerable to strong electromagnetic interference (EMI): requires good shielding design.

Surface water stains or droplets may cause accidental touch or misidentification (requiring waterproof/wet touch algorithm).

Typical applications: smartphones, tablets, high-end POS machines/Kiosk, ATMs, modern in car infotainment systems, smart home control panels, and most consumer electronics.

3. Infrared Touch Screen

Principle: Arrange dense X-axis and Y-axis infrared emitting and receiving tubes on the screen frame (usually a protective frame) to form a cross infrared grid. Finger touch blocks light, and the controller detects the obstruction point to determine its position.

advantage:

Extremely high transmittance (close to 100%): The display effect is lossless.

Surface uncoated: The touch surface is made of pure glass (or acrylic), which is very sturdy and durable, resistant to scratches and chemical corrosion.

Support for multi touch: depends on the controller's capability (can support dozens or even more).

Supports various touch methods: finger (any glove), pen, glove operation, and even non-conductive objects.

Strong ability to resist electromagnetic interference (EMI).

Easy to clean and disinfect: The surface is smooth and seamless.

Disadvantages:

Thick border: affects the overall appearance design of the device (narrow border design is difficult and costly).

Susceptible to environmental light interference: Direct exposure to strong light (especially infrared light) may cause false triggering or failure.

Surface dust/dirt accumulation may block light and cause accidental contact. **

Cost: Small size has a higher cost, while large size has a relative advantage in cost.

Typical applications: large-sized interactive whiteboards, educational all-in-one machines, large information kiosks (such as airports and shopping malls), medical imaging equipment (such as PACS reading screens), industrial environments (requiring thick gloves or harsh environments), outdoor high brightness applications (requiring anti light design).

4. Surface Acoustic Wave (SAW) touch screen

Principle: Install transmitting and receiving piezoelectric transducers at the edge of the screen. Spread ultrasonic waves on the surface of glass. Finger touch absorbs some of the sound wave energy, and the controller detects the location of energy loss.

advantage:

Extremely high transmittance and clarity.

Excellent touch accuracy and linearity.

The surface is made of pure glass, which is very durable.

Supports multi touch (usually two-point).

Disadvantages:

Very sensitive to surface pollution: Water droplets, oil stains, and dust can absorb sound waves, leading to accidental contact or misidentification.

Surface scratches or potholes can interfere with the propagation of sound waves.

The cost is relatively high.

The border is relatively thick.

Typical applications: applications that require extremely high precision (such as drawing boards), some industrial control, and clean room equipment (environments with low pollution sensitivity).

Touch screens:https://www.idtdisplay.com/products/industrial_touch_screen