Industrial LCD Screen Selection Guide

Industrial LCD screen selection guide: 6 core dimensions and practical avoidance pitfalls,Basic dimensions: size and resolution,Resolution matching strategy,Industrial grade core parameters: environmental adaptability,Interface protocol: determines system

Industrial LCD Screen Selection Guide

The ultimate guide for industrial LCD screen selection tailored for industrial procurement, hardware engineers, and project decision-makers, combined with technical parameter analysis, scenario based cases, and pit avoidance strategies.

Industrial LCD screen selection guide: 6 core dimensions and practical avoidance pitfalls

I. Basic dimensions: size and resolution

The Golden Rule of Size Selection

Priority for standard sizes: 5.0 ", 7.0", 10.1 ", 15.6" and other standard sizes (cost reduction of over 30%, delivery time ≤ 7 days)

Non standard screen selection: Custom mold fee starts at $5K, delivery time is 8-12 weeks (need to evaluate mass production requirements)

2. Resolution matching strategy

Application scenarios | Recommended Resolution | Interface protocol |

Industrial HMI | 800×480 (WVGA) | RGB Or LVDS |

Medical imaging display | 1920×1080 (FHD) | eDP Or MIPI |

Outdoor POS machine | 1024×768 (XGA) | LVDS(Strong anti-interference) |

II. Industrial grade core parameters: environmental adaptability

Temperature Range Elimination

Fee level: 0~50 ℃ → Low cost but prone to black screen

Industrial grade: -30~85 ℃ (wide temperature LCD+IC, 1.5 times higher price but 3 years longer lifespan)

* ⚠ Pit point: Failure to indicate storage temperature (-40~90 ℃) may result in transportation damage

*Seismic resistance and durability

Backlight lifespan ≥ 50000 hours (industrial screen benchmark)

Anti vibration ≥ 1.5G (compliant with MIL-STD-810G military standard)

▶ Due to insufficient seismic resistance, the failure rate of a certain AGV's onboard screen was 37% in 3 months. After upgrading to a 1.8G seismic resistant screen, the failure rate was reset to zero

III、 Interface protocol: determines system compatibility

Comparison of mainstream interface performance

Interface type | Transmission broadband | Immunity | Industrial scene recommendation index |

LVDS | 2.5Gbps | 5 stars | Required (Industrial Control/HMI) |

eDP | 5.4Gbps | 3 stars | Recommended (medical/high brush) |

MIPI | 10Gbps | 2 stars | Careful selection (EMI sensitive scenarios) |

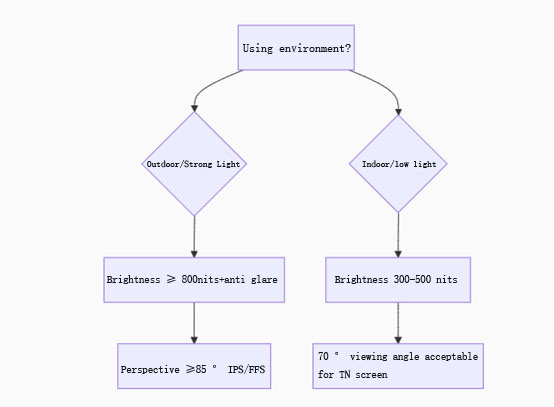

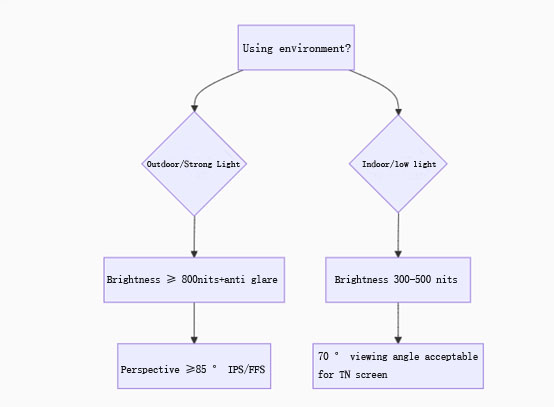

IV. Optical performance: Scene based decision tree

Outdoor gas station screen selection with 800nits IPS screen, increasing visibility by 90% under strong light

V. The lifeline of the supply chain: delivery time and certification

Delivery time trap

Standard product: Inventory ≤ 3 days, discontinued models require confirmation of spare parts quantity (e.g. AUO G121STN02.1)

Change backlight:+15 days (with reserved time)

Authentication non optional

Medical equipment: ISO 13485+IEC 60601

Car equipment: AEC-Q100+TS16949

⚠ A batch of containers of industrial control screens exported to Europe were seized due to the lack of CE certification

6、 Ultimate Avoiding Pits: Sample Test Checklist Aging Test: 72 hour continuous lighting → Check for bright/dark spots Temperature Change Test: -30 ℃ cold start → 60 ℃ high temperature screen drag detection Compatibility Verification:

AUO LCD DISPLAY:https://www.idtdisplay.com/products/AUO_LCD_Displays/