Comparison of Touch Screen Frame Bonding and Full Lamination Technologies

Comparison of Touch Screen Frame Bonding and Full Lamination Technologies,Air bonding and full lamination are two mainstream processes, and their advantages and disadvantages are compared as follows

Comparison of Touch Screen Frame Bonding and Full Lamination Technologies

In the fields of industrial displays, smart terminals, and consumer electronics, the bonding technology of touch screens directly affects the display effect, durability, and cost of devices. Air bonding and full lamination are two mainstream processes, and their advantages and disadvantages are compared as follows:

1、 Differences in Technical Principles

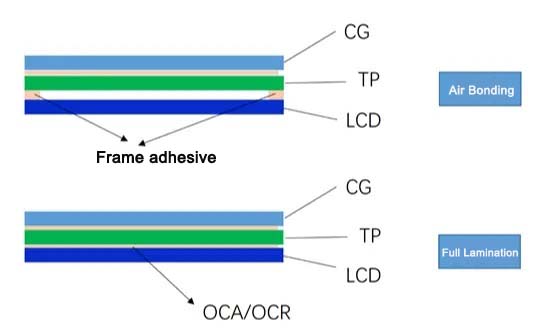

1. Frame bonding (Air Bonding)

Principle: The touch screen and display screen are bonded only at the border with double-sided tape or sealing tape, leaving an air layer (about 0.2-0.5mm) in the middle.

Typical applications: early industrial equipment, low-end consumer electronics (such as entry-level tablets).

2. Full lamination

Principle: Use OCA/Optical Clear Adhesive to fully bond the touch screen and display screen without any air gaps.

Typical applications: high-end industrial control equipment, medical instruments, vehicle control screens, smartphones.

2、 Comparison of core strengths and weaknesses

Comparing dimensions | Air Bonding | Full Lamination |

Display effect | ❌ The air layer causes high refractive index of light, easy reflection, and poor outdoor visibility; ❌ The light transmittance is low (about 85%), and the image appears gray. | ✅ No air layer, light transmittance ≥ 92%, brighter colors; ✅ AR coating can be integrated and is clear under strong light. |

Touch sensitivity | ❌ The air layer causes high touch delay, and multi touch is prone to drift. | ✅ The touch layer is closely attached to the display layer, with a faster response speed (≤ 10ms). |

Durability and Protection | ❌ The air layer is prone to dust and water vapor, and may peel off after long-term use; ❌ Poor seismic resistance, prone to delamination under external impact. | ✅ Fully sealed structure dustproof and waterproof (IP65 level protection); ✅ Strong impact resistance, suitable for vibration environments (such as vehicle mounted equipment). |

Thickness and weight | ❌ The air layer increases the overall thickness (about 0.3-1mm), making the equipment bulky. | ✅ The seamless design is thinner and lighter (20% -30% thinner than frame stickers). |

Production process and cost | ✅ The process is simple, the yield rate is high, and the cost is low (saving 30% -50%). | ❌ Vacuum bonding equipment is required, the process is complex, and the yield rate is low; ❌ High cost (OCA adhesive accounts for 15% -25% of material cost). |

Repair and rework | ✅ Easy to disassemble and repair, low cost of replacing single-layer components. | ❌ The integrated structure requires a complete replacement if damaged, resulting in high maintenance costs. |

3、 Recommended Typical Application Scenarios

1. Applicable scenarios for frame stickers

Budget limited projects: Industrial control panels and low-end self-service terminals with low display performance requirements.

Short term use equipment: exhibition temporary equipment, test prototypes, and other scenarios that do not require long-term dust prevention.

2. Full fitting required scene

Outdoor strong light environment: such as construction machinery display screens and photovoltaic power station monitoring terminals, high brightness and anti reflection are required.

High protection requirements: medical equipment (operating room anti liquid splashing), vehicle mounted central control (moisture-proof and shockproof).

High precision requirements for touch control: industrial robot operation interface, precision instrument touch screen.

4、 Technological upgrade trend

1. Frame sticker improvement plan:

Using high transmittance explosion-proof film (such as PET+SiO ₂ coating), the transmittance is increased to 88%;

Upgrade the frame adhesive to silicone with stronger weather resistance (temperature resistance -40 ℃~120 ℃).

2. Full lamination innovation direction:

Flexible full lamination: Suitable for curved screens (such as car curved instrument panels), using UV cured OCA adhesive;

Ultra thin design: By using 0.15mm ultra-thin glass and micrometer sized OCA adhesive, the thickness is reduced to below 0.5mm.

5、 Selection suggestions

Prioritize full lamination: If the device requires long-term outdoor operation, high-frequency touch, or high protection level (IP54 or above).

Optional frame stickers: only used for indoor fixed environments, cost sensitive projects, or short-term transition plans.

Summarize:

The trade-off between frame pasting and full lamination is essentially a balance between cost and performance. Under the trend of industrial intelligence and consumer upgrading, full lamination technology is gradually becoming the mainstream choice for high-end devices with better display and durability, while frame stickers still maintain cost advantages in the mid to low end market. Enterprises need to make comprehensive decisions based on product positioning, usage environment, and lifecycle.

Touch Screen:https://www.idtdisplay.com/products/industrial_touch_screen/